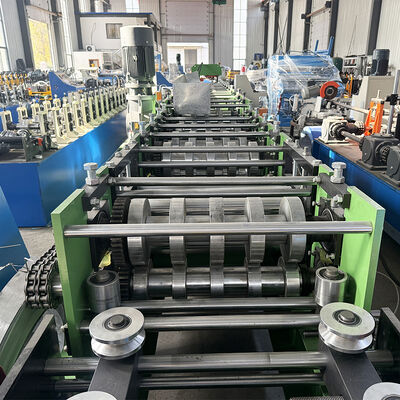

Máquina de Conformação de Rolo para Fabricação de Treliças de Telhado C Purlin com Parada Automática

Esta máquina de conformação de rolo de aço CZ totalmente automática permite a conversão rápida entre perfis de aço C e Z, permitindo mudanças rápidas de especificação de 80-300mm em um minuto. O sistema avançado de corte de conformação fornece corte contínuo em toda a faixa sem troca de ferramentas. As características incluem ajuste automático de centralização na porta de alimentação, corte de comprimento fixo preciso e altas velocidades de produção de 8-15m/min, reduzindo significativamente os custos de mão de obra, ao mesmo tempo em que melhora a eficiência da produção.

Especificações Técnicas

| Parâmetro |

Especificação |

| Largura do Material de Alimentação |

De acordo com o perfil |

| Espessura do Material de Alimentação |

Máx. 3,0 mm |

| Largura da Longarina |

100-300mm |

| Altura da Longarina |

40-80mm |

| Estações de Rolo |

14 estações |

| Material do Rolo |

Gcr15, tratamento de têmpera, dureza 55-58 |

| Velocidade de Formação |

10-15 m/min |

| Motor Principal |

15 kw |

| Método de Acionamento |

Transmissão por corrente |

| Potência Hidráulica |

5,5kw |

| Sistema de Perfuração |

Pré-perfuração hidráulica |

| Material do Molde de Perfuração |

Cr12 |

| Sistema de Corte |

Pré-corte hidráulico |

| Material da Lâmina |

Cr12 |

| Tolerância |

±1.5mm |

| Voltagem |

380V 50Hz 3 fases |

| Peso da Máquina |

13 toneladas |

| Comprimento da Máquina |

10m |

| Sistema de Controle |

PLC Panasonic |

| Capacidade do Desbobinador |

5 toneladas |

Principais Características

Estrutura de Alta Resistência

Projetada com comportamento mecânico superior para máxima durabilidade e desempenho sob uso industrial pesado.

Rolos de Precisão

Os rolos passam por duas usinagens CNC e processos de têmpera, atingindo uma dureza de HRC 58-62 para vida útil prolongada.

Ajuste Automático de Largura

Capacidade flexível de mudança de largura de 80-300mm como padrão, com capacidade máxima de até 120×350mm.

Sistema de Corte Universal

Tamanhos de corte flexíveis com materiais de corte Cr12 e MOV. Intervalo de manutenção: afiação necessária a cada 20.000-30.000 ciclos de corte.

Componentes de Controle Premium

- Controlador PLC - Siemens

- Transdutor - Yaskawa

- Codificador - KOYO

- Outros Componentes Eletrônicos - Schneider

Vantagens da Máquina

- Mudanças rápidas de especificação da longarina em 5-10 minutos

- O sistema de corte e perfuração rápido C/Z de quarta geração elimina a necessidade de troca de moldes de corte

- Superior aos sistemas tradicionais que exigem trocas frequentes de moldes, economizando tempo e espaço de armazenamento

Embalagem e Pagamento

Componentes importantes são protegidos com óleo antiferrugem, rolos e eixos são embalados em espuma, e estações hidráulicas, caixas de controle PLC, peças de reposição e pequenos componentes são embalados em caixas de madeira compensada. Todos os componentes são fixados com segurança com fio de aço para transporte em contêiner.

Condições de Pagamento: 30% T/T após a assinatura do contrato, saldo devido antes da entrega.

Garantia e Suporte

Garantia: 18 meses com suporte técnico vitalício

Treinamento: Um técnico por uma semana (inclui instalação e ajuste)

Custos de Treinamento: O comprador cobre visto, passagem de volta, alimentação, acomodação e USD $100/pessoa/dia de salário.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!